Manesar, Gurugram, Haryana

- GST NO. : 06AAJCG0882C1ZT

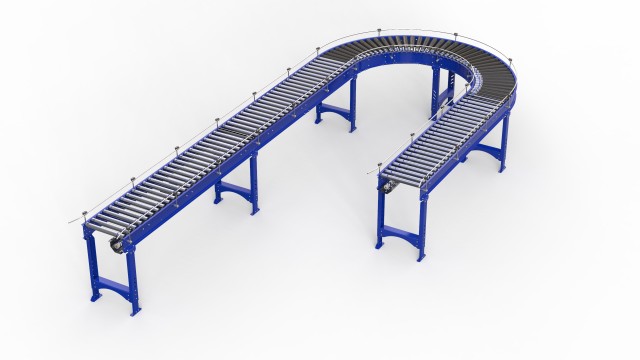

Industrial Roller Conveyor

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Stainless Steel & Iron |

| Finishing | Polished |

| Driven Type | Motor |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

The Evolution of Roller Conveyer Belts

- Roller conveyer belts have come a long way since their inception in the late 19th century. Initially used in coal mines, these belts were made of leather and wood, and were powered by hand or steam engines.

- With the advent of the Industrial Revolution, roller conveyer belts became more widespread and were used in various industries such as manufacturing, food processing, and transportation. The materials used to make these belts also evolved, from leather and wood to rubber and synthetic materials that are more durable and efficient.

- Roller conveyer belts offer a multitude of advantages for manufacturing and distribution industries. First and foremost, they increase efficiency by allowing for quick and easy transportation of goods from one point to another. This not only saves time but also reduces the risk of damage to the products being transported.

- In addition, roller conveyer belts are highly customizable and can be tailored to meet specific industry needs. They can be designed to handle heavy loads, operate at high speeds, and even navigate through tight spaces. Furthermore, roller conveyer belts require minimal maintenance, which translates to lower costs and increased productivity.

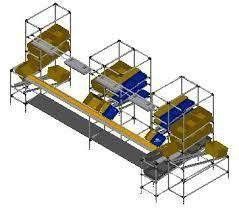

Applications of Roller Conveyor:

- Roller conveyer belts are widely used in the food and beverage industry for transporting products such as bottles, cans, and packages. The belts can be customized to handle specific product sizes and shapes, making them an ideal solution for efficient and streamlined production processes.

- In the automotive industry, roller conveyer belts are commonly used for assembly line production, where they transport car parts from one station to another. This helps to reduce manual labor and increase efficiency in the manufacturing process.

- E-commerce companies also rely heavily on roller conveyer belts for their distribution centers. The belts are used to transport packages and parcels from one area to another, allowing for quick and efficient order fulfillment.

Types of Roller Conveyer:

Gravity roller conveyer belts are the most common type of conveyer belt. They use the force of gravity to move items along the belt. These belts are ideal for transporting lightweight items over short distances. Gravity roller conveyer belts are often used in packaging and shipping industries.

Powered roller conveyer belts use electric motors to move items along the belt. These belts are ideal for transporting heavy items over long distances. Powered roller conveyer belts are often used in manufacturing and distribution industries.

Future of Roller Conveyer

As we look towards the future of roller conveyer belts, the possibilities are endless. One trend that is likely to continue is the integration of automation technology into these systems. This will allow for even greater efficiency and productivity in manufacturing and distribution industries.

Another area of potential innovation is the use of sustainable materials and energy sources in the production and operation of roller conveyer belts. As companies become more environmentally conscious, they will seek out solutions that reduce their carbon footprint and promote sustainability.

Looking for "Industrial Roller Conveyor" ?

Explore More Products