Manesar, Gurugram, Haryana

- GST NO. : 06AAJCG0882C1ZT

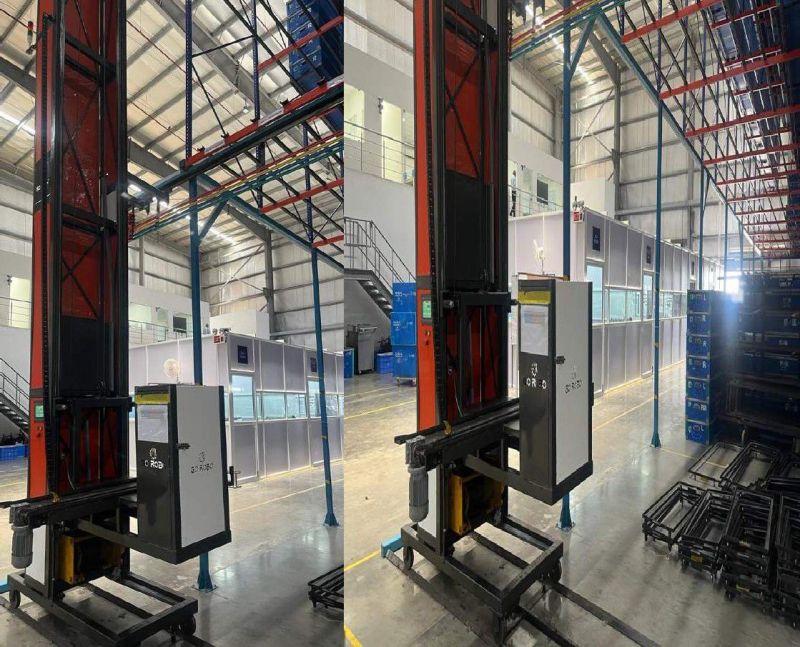

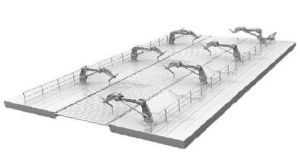

Automated Storage Lift Rack

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Color | Multi Color |

| Advantages | Space Saving Cost Cutting |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Country of Origin

India

Dimension(L*W*H)

Fully Customizable

Load Capacity

2 Ton/ layer

Surface Finish

Color Coated

Application

Warehouse

Brand Name

Go Robo

Storage Racks:

The basic infrastructure for storing goods. Racks can be configured in various ways {o accommodats different types and sizes of items.

Automatic Lifters (Robotic Systems)

- Automated machines or robotic systems designed to move vertically within the storage system.

- Thesa lifters can retrieve or deposit items on different shelves of the storage racks.

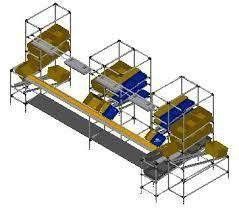

Control System:

- Software that manages and controls the mevement of the automatic liftars.

- It can be programmed to optimize storage space, reduce retrieval times, and enhance overall systam efficiency.

Sensors:

- Various sensors (such as proximity sensors, weight sensors, and cameras) to detect and navigate around obstacles.

- These sensors help prevent collisions and snsure accurate positioning of items.

Communication System:

- Connectivity for real-time communlcation between the control system and the automatic lifters.

- This enables quick adjustments, monitoring, and maintenance.

Benefits:

- Increased Efficiency : Automation reduces the time and effort required for tasks like picking and storing items.

- Optimized Storage : Automated systems can optimize storage space by utilizing vertical space more efficiently.

- Reduced Labor Costs : By automating tasks that would otherwise require human labor, operational costs can be reduced.

- Accuracy and Precision : Automated systems can be highly accurate and precise in picking and placing items, reducing errors.

- 24/7 Operations: Automated systems can operate continuously, improving the overall speed and responsiveness of the storage process.

- Adaptability : These systems can be designed to handle a variety of items and adapt to changes in inventory.

Looking for "Automated Storage Lift Rack" ?

Piece

Explore More Products